- VeraBS

-

Acrylic Display

- Acrylic Trophy Awards

- Jewelry Display Rack

- Cosmetic Display

- Watch Display Rack

- Commodity Display

- Glasses Display Rack

- POP Display Rack

- Window Display

- Acrylic Photo Frame

- Acrylic Letters LOGO

- Acrylic Dome

- Acrylic Brochure

- Acrylic Service Tray

- Acrylic Book Stand

- Acrylic Storage Box

- Lipstick Storage Display

- Organizer Acrylic

- Acrylic Lighting

- Customized Display

-

Acrylic Industry

- Acrylic Restaurant Supplies

- Iphone Display Stand

- Acrylic Display Stand

- Acrylic Tray Box

- Acrylic Covers

- Acrylic Window Display

- Acrylic Award

- Acrylic Sign

- Acrylic Holder

- Riser Display Stand

- Cellphone Display

- Lipstick Display Stand

- Jewelry Organizer

- Acrylic Organizer Case

- DIY LOGO

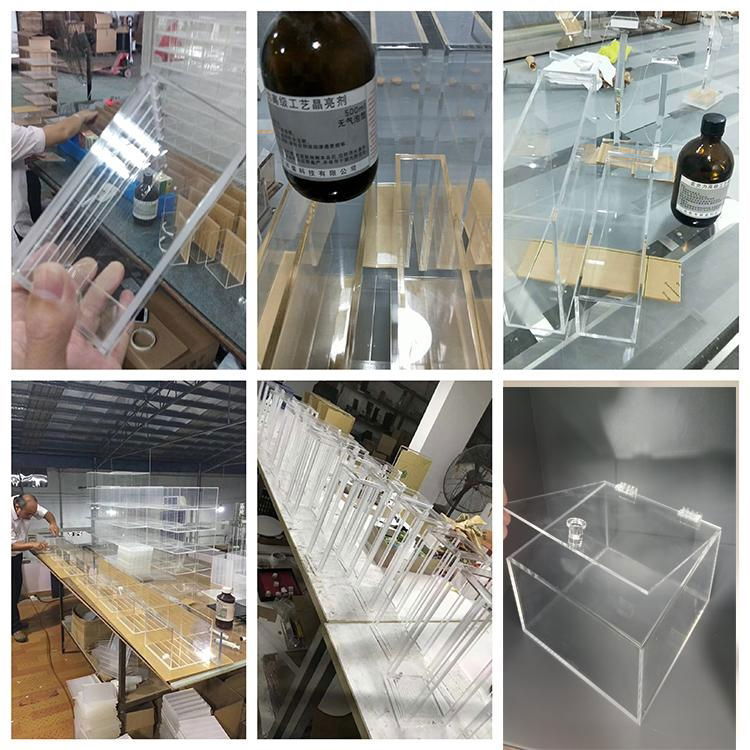

- Quality Shipment Asurance

- Lab Acrylic Product

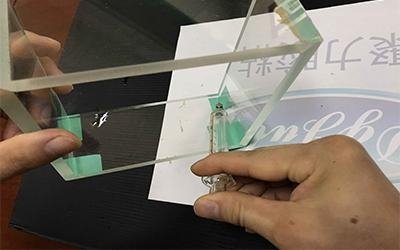

- Customized Acrylic

- Catalogue

- Contact Us